Intelligent Pigging, Advance NDT, Conventional NDT, Engineering Assessment

Pipeline, Static Equipment using conventional & Advance NDT

Re-engineering design, fit for service and etc.

Procurement, Oil and Gas & Petrochemical Industries

PT. Lynx Java Global is here for you. Whether you need of multi-disciplined of NDT inspection, engineering (assessment) and repair methodology recommendation of your valuable assets in high quality deliverable with effective and efficient interm of time and cost, we provide structural service of lifting equipment or piping support. Expert opinion of an engineering for piping, pipeline and pressure vessel. Perform fit for service or purpose assessment including save repair method, work with effisien and optimize budget.

Become the Leading Company to provide high quality engineering, inspection, and quality control or assurance service as solutions to our client’s.

Advance NDT – PAUT, Eddy Current, Conventional NDT – UT, MT, PT, Intelligent Pigging of piggible and/or un-piggible line, Integrity Assessment, Material Procurement & etc.

NDT – PAUT, Eddy Current and etc.

weldment Quality, Flange Inspection ect

Perform PAUT Scanning at Horizontal and Vertical Weldment Storage Tank, Closed Drain, Dissimilar Material and Other Static Equipment

Penetrant & Developer Aplycation

Provide good quality of in-line inspection

MFL Tool, Geometry Tool, Illegal Tapping tool detection

Field Verification and Repair

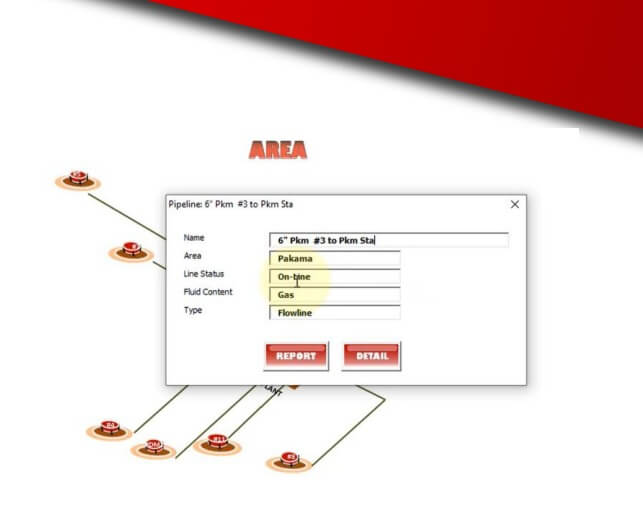

Develop data management system for client equipment (piping, pipeline and etc.)

Provide good quality of in-line inspection MFL Tool, Geometry Tool, Illegal Tapping tool detection

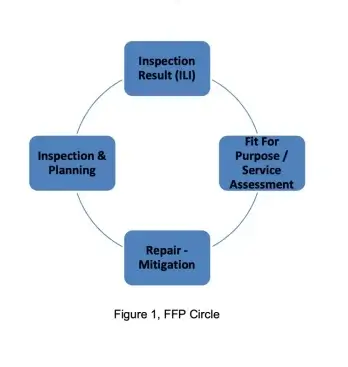

The use of the latest inspection methods and equipment will assist in obtaining the maximum life expectancy from a pipeline reducing the overall operating costs. With the variety of inspection methods available, it is important to select the method that

Intelligent Pigging, Advance NDT, Conventional NDT, Engineering Assessment.

NDT – PAUT, Eddy Current and etc.

weldment Quality, Flange Inspection ect

Perform PAUT Scanning at Horizontal and Vertical Weldment Storage Tank, Closed Drain, Dissimilar Material and Other Static Equipment

Penetrant & Developer Aplycation

Provide good quality of in-line inspection

MFL Tool, Geometry Tool, Illegal Tapping tool detection

Field Verification and Repair

Develop data management system for client equipment (piping, pipeline and etc.)

Provide good quality of in-line inspection MFL Tool, Geometry Tool, Illegal Tapping tool detection

The use of the latest inspection methods and equipment will assist in obtaining the maximum life expectancy from a pipeline reducing the overall operating costs. With the variety of inspection methods available, it is important to select the method that

Perform field verification based on inspection data included repair